How to Achieve a Balance Between "High Efficiency" and "Stability" in a 24-Cavity PET Preform Mold

—A Report on a Mass Production Project of 1.5L Mineral Water Preforms for a Certain Brand

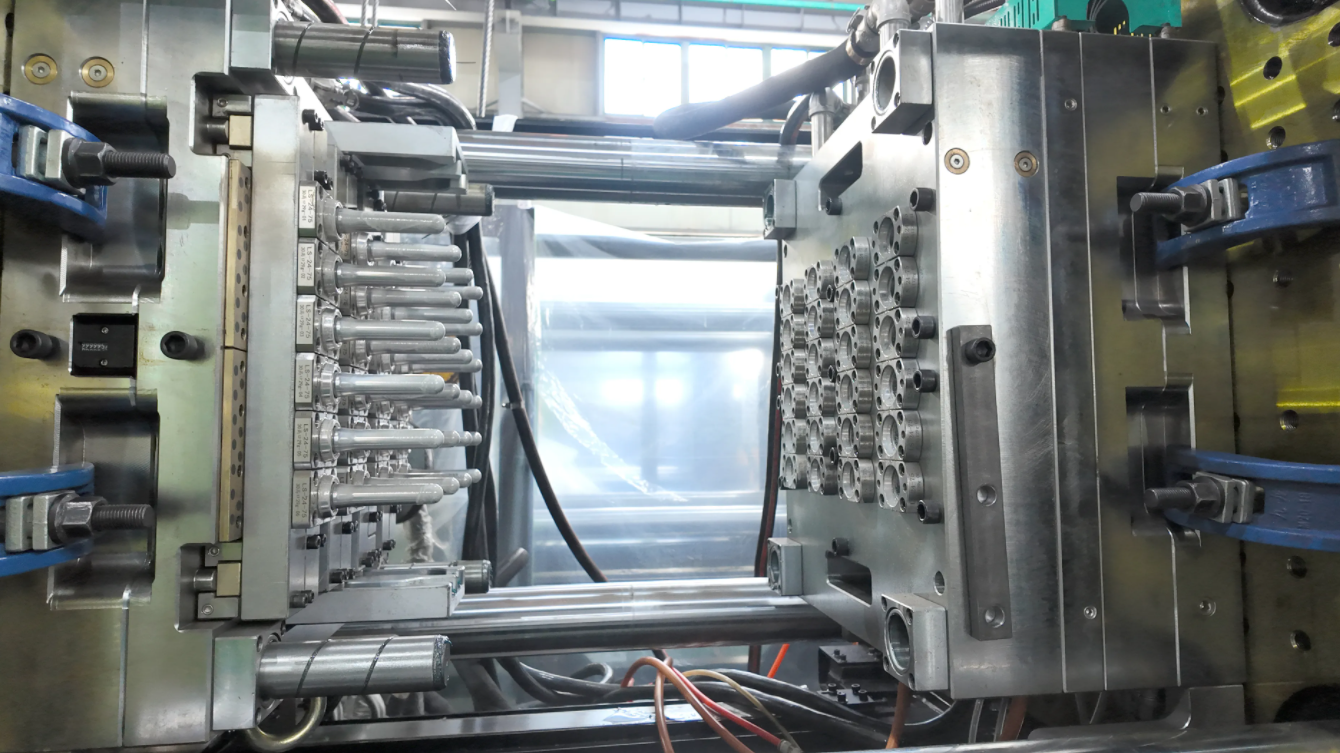

Last month, we delivered a 24-cavity PET preform mold to a large beverage packaging company in East China, matching it with our high-speed injection molding machine. It has now achieved a stable mass production of over one million preforms per day. This project is typical, and some of the problems encountered and solved are worth sharing for discussion.

I. Core Client Needs: Not Just "Multiple Cavities," But "Each Cavity is Identical"

The client's needs were very clear:

1. Extreme Efficiency: To meet the huge demand for 1.5L bottled water during peak season, it is essential to increase the output per mold.

2. Absolute Stability: With 24 cavities, any fluctuation (weight, size, crystallinity differences) will lead to a decrease in yield during blow molding and frequent online detection alarms, which is unacceptable for the production line.

3. Controllable Costs: While ensuring the first two requirements, maintenance must be convenient, and the mold life must be long.

Simply put, what they wanted wasn't 24 cavities "working," but 24 "identical" cavities "working synchronously and stably."

II. Our Solution: Achieving "Balance" in Every Detail

Faced with the classic challenges of large flow length differences and uneven heat distribution brought about by 24 cavities, we worked with the mold team to finalize several key design decisions:

1. Hot Runner System: Selection and Layout are the Lifeline

• Adopting a "multi-point valve pin + simultaneous opening of hot nozzles" system. This was a crucial decision. Compared to single-point valve pins, it ensures that the melt fills all cavities simultaneously with more consistent pressure and temperature, fundamentally reducing differences caused by varying filling sequences.

• Layered and zoned precise temperature control. The hot runner plate is divided into independent temperature control zones, providing temperature compensation for "weaker" runners farther from the main inlet, ensuring a consistent melt state at each nozzle tip.

2. Cooling System: "Conformal Cooling" and Efficient Layout

• Cooling is the core of a preform mold. We used a mold core made of a high thermal conductivity material and designed an internal spiral turbulent cooling channel to ensure that each preform is cooled quickly and evenly. Uneven cooling directly leads to differences in preform shrinkage and crystallinity.

• The water channel layout has been repeatedly optimized through mold flow analysis to ensure that the cooling efficiency deviation of the 24 cavities is controlled within 5%.

3. Mold Structure and Precision: Guarantee of Rigidity and Fine-Tuning

• Large mold plate design with ultra-high rigidity. The huge injection pressure brought by 24 cavities requires the mold plate to have extremely high resistance to deformation, which is the basis for long-term stability.

• Key components (such as mold cores and cavities) are made of imported high-hardness steel and are all precision machined in a temperature-controlled workshop to ensure cavity consistency.

• A simple fine-tuning mechanism is reserved. During the trial molding stage, the filling can be balanced by fine-tuning the shims of individual hot runners, which is crucial for the final calibration of multi-cavity molds.

III. Collaboration with Injection Molding Machines: "A Good Horse Needs a Good Saddle" No matter how well the mold is designed, it ultimately needs to run on the machine. Our high-speed injection molding machine played a crucial role:

• Extremely high injection speed and response: Ensures rapid filling of PET melt in optimal condition, avoiding material degradation and uneven performance caused by shear overheating or premature cooling.

• Stable closed-loop control: The machine's precise control of injection pressure and holding pressure is the last line of defense against microscopic differences in the mold, ensuring that the process parameters for each mold are tightly controlled within a narrow, optimal range.

• Fast cycle time: Combined with a highly efficient cooling mold, the mold opening and closing time and ejection time are optimized to the extreme, achieving a stable cycle time of less than 11 seconds, fully leveraging the efficiency advantage of the 24 cavities.

IV. Project Results and Customer Value After three weeks of trial molding and parameter optimization, the project achieved its goals:

• Production efficiency: The cycle time stabilized at 10.8 seconds, with a theoretical daily production capacity exceeding 1.1 million preforms, fully meeting customer needs.

• Product consistency: Randomly selected preforms from any cavity showed a weight tolerance stable within ±0.15 grams, with mouth size and crystallinity fully meeting standards.

• Production Stability: Continuous 72-hour production verification showed no downtime or quality fluctuations due to mold issues, with the blow molding production line yield exceeding 99.7%.

V. Lessons Learned and Reflections This project once again confirms a principle: competition in multi-cavity molds lies not in "quantity," but in "uniformity." It tests the systematic integration capabilities from hot runner selection, cooling design, machining precision to injection molding processes. A weakness in any link will be magnified exponentially by the number 24.

For us, successful delivery is not the end. This mold is now integrated into our remote monitoring system; its continued stable operation is the true embodiment of the shared value between us and our client.